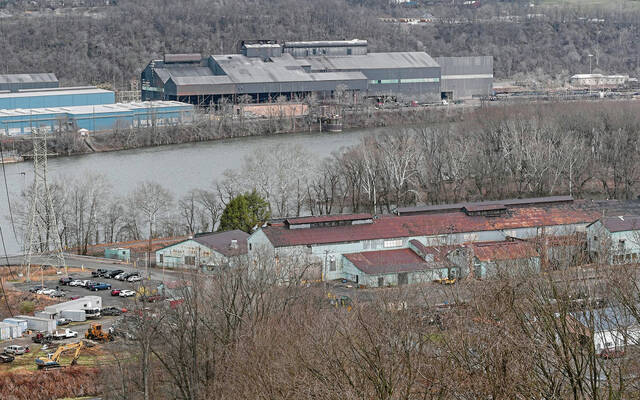

Gary residents hoped the new partnership between U.S. Steel and Japanese company Nippon Steel would mean changes to how much coal is being used and how much emissions are being released, but that’s not what’s in the works.

CBS News Chicago Investigators revealed the toll steel mills in Gary are accused of taking on the health of the community, and the medical research working to connect exposure to certain cancers.

Since Nippon Steel acquired U.S. Steel, the Japanese company announced a decision to reline a blast furnace at the Gary Works plant. The choice reflects the commitment to continuing to make steel the way they always have in Gary: with coal.

Gary is a steel town, and the industry is critical to its economy, but CBS News Chicago Investigators has exposed the significant industrial pollution in Northwest Indiana which partially stems from the steel production facilities in the area, as well as the health impact for people living there. Residents of Gary have higher risks for developing asthma and some cancers, and Gary was failing to meet federal air quality standards.

“I think that what we’ll start to see with those rollbacks is increases in visits to doctor’s offices and emergency rooms from people suffering from the impact and effects of those pollutants in the community,” said Dr. Janet Seabrook, health commissioner for the City of Gary.

Since those reports, the community has come together to fight for cleaner air and to hold polluters accountable. But international watchdog group SteelWatch calls the latest move for steel production facility Gary Works – the decision to invest $350 million to reline a blast furnace –bad for the community.

“Retaining blast furnaces is just going to lock Gary irresponsibly into more decades of pollution,” said Roger Smith with SteelWorks. He is based in Japan, leading the nonprofit’s work in Asia.

Smith explained the reline is a 15- to 20-year commitment to making the steel the same way, something that has some in Gary concerned about their health and environment.

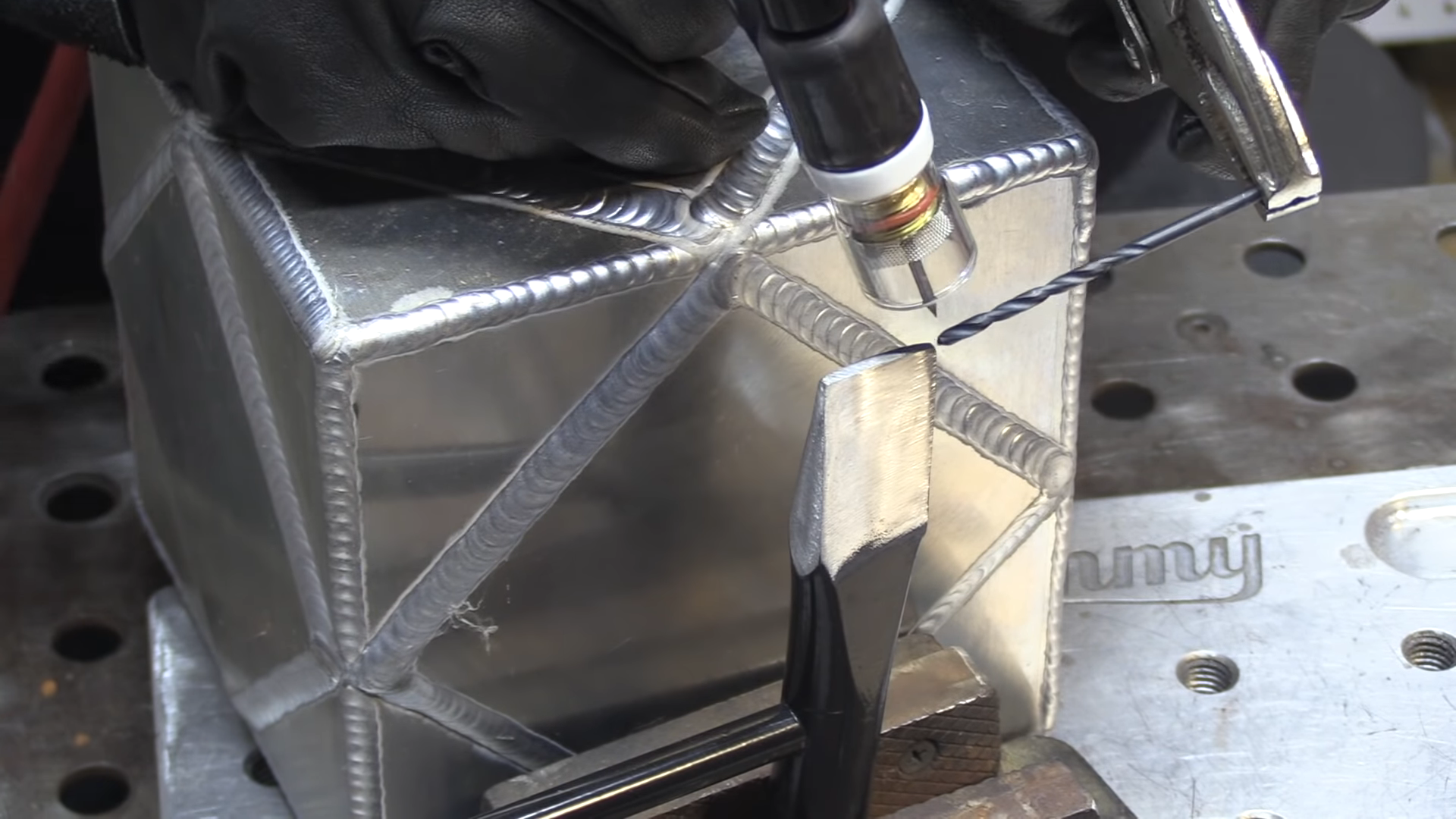

U.S. Steel has invested in cleaner steel production elsewhere, with plans to build a sustainable facility in Arkansas that uses electric furnaces which the company says will lower greenhouse gas emissions by 75%.

“When we think about Japanese technology, we think about, like, bullet trains, you know, we think about the latest and greatest. Gary Works is a facility from the age of steam. Nobody’s gonna thank Nippon Steel for a new generation of steam locomotives. I think we want the latest and greatest technologies,” Smith said.

CBS News Chicago reached out to U.S. Steel and requested an interview on their Gary plans, but no one would speak on camera.

They did provide answers in writing. A spokesperson explained that the auto industry is still heavily reliant on coal-based steel and to change the process would mean shutting down and demolishing the Gary plant entirely, essentially costing jobs.

FULL STATEMENT FROM U.S. STEEL

First, to the extent the inquiry pertains to the blast furnace reline, the reline is routine maintenance and will not lead to increased coal use or raw steel production.

The improvements to the Gary Works facility, including the Hot Strip Mill and steel shop improvements, are about making the steel we already produce cleaner, more efficient, and higher quality, especially for the auto industry. The billions being invested will update equipment, allowing for new products to be created and enabling us to use less coke in the steelmaking process. These upgrades directly support community health while protecting thousands of good-paying jobs, keeping the plant competitive and able to provide generational job security.

2. Why is a clean steelmaking process planned in Arkansas but not in Northwest Indiana?

The two facilities are fundamentally different.

Our Big River Steel Works was designed from scratch around electric arc furnace technology, prior to U. S. Steel acquiring it and we later invested and built Big River Steel 2. Gary Works is a long-established integrated mill that supplies critical steel to the auto industry — more than 3 million tons annually of specialized automotive steel grades that cannot be produced through EAF technology at this point.

3. Why isn’t Nippon’s investment being used to create a non coal-based process at Gary Works?

Building a non-coal-based process in Northwest Indiana would be devastating to the community, Company, and its employees. Converting Gary Works to an Electric Arc Furnace facility would mean shutting down the entire plant, demolishing it, and building new facilities. This would effectively shutter the plant for years, leading to significant losses and greatly reducing our ability to serve the automotive market.

The activist authors of these studies demonstrate a fundamental lack of insight into the economic and technological realities of the steel industry, as well as zero concern for the job losses their recommendations would cause.

We are committed to $11 billion in overall investment by the end of 2028, across our US footprint, through our partnership with Nippon Steel. This historic investment is focused on modernizing and improving Gary Works as it operates today, ensuring generational job security rather than tearing it down.

This path strengthens Gary Works and preserves jobs. Following recommendations uninformed by technical and economic realities would do the opposite.

Certain advocates have made much about the possibility of using hydrogen as fuel for steel production. Hydrogen at the scale necessary for steel production is currently unavailable and would be so economically impractical it would make our steel uncompetitively expensive, leading to job losses.