It began with a faint chemical smell. As air fryers became standard kitchen appliances, a troubling byproduct emerged alongside low-oil cooking: the acrid scent of heating plastics and synthetic coatings. For regulators, toxicologists, and a growing segment of consumers, this phenomenon has become the frontline of a broader reckoning over ‘forever chemicals’.

Now, an emerging appliance manufacturer is attempting to capitalise on this shift by returning to stainless steel. Founded in 2021, the Chinese home appliance brand HYSapientia promotes a ‘Safe Cooking With Steel’ philosophy, a calculated wager that eliminating plastics and chemical linings will secure market share in an increasingly health-conscious landscape.

The initial appeal of air fryers rested on convenience, but the mechanics of many standard models rely heavily on per- and polyfluoroalkyl substances, or PFAS, for non-stick linings, alongside Bisphenol-A, known as BPA, within plastic housings. PFAS, utilised for decades to create grease-resistant coatings, are notoriously persistent in the environment and the human body.

Prolonged exposure has been linked by medical researchers to elevated cholesterol, immunosuppression, and an increased risk of certain cancers, while BPA is an established endocrine disruptor. This has elevated the safety of countertop appliances from a niche consumer worry to a mainstream regulatory target.

Momentum for legislative intervention is accelerating globally. In the United States, California has enacted legislation mandating the disclosure of toxic chemicals like PFAS in cookware, establishing a precedent for supply chain transparency. Simultaneously, regulators in the European Union are drafting a sweeping universal restriction on thousands of PFAS compounds, with a decisive ruling expected by 2027.

Consumers are increasingly front-running these regulators. Recent market data indicates that 65 per cent of US adults harbour concerns regarding PFAS in their cookware. Dr Bruce Jarnot, a board-certified toxicologist monitoring the sector, advises consumers to specifically seek out air fryers marketed as PFAS-free.

Consequently, the era of unquestioned reliance on synthetic non-stick coatings appears to be sunsetting. Against this anxious backdrop, Jimmy Wang, a UK-educated entrepreneur, established HYSapientia in Ningbo, China. Observing both the exponential growth of the air fryer category and the looming regulatory cliff for plastics, Wang directed the company to engineer a product devoid of synthetic coatings.

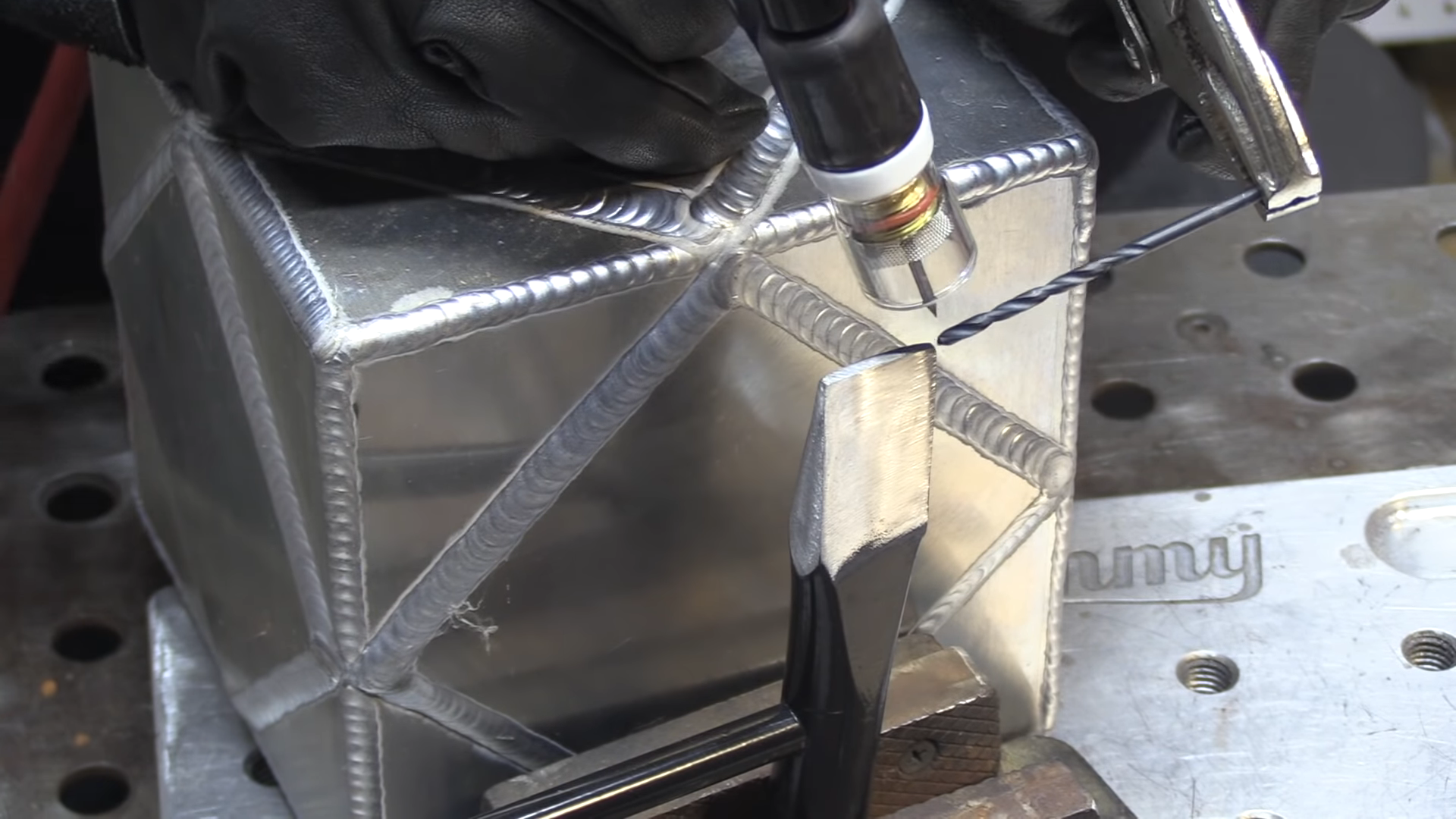

The company’s flagship 24-litre Air Fryer Oven, launched in late 2023 across European and North American markets, represents a strategic departure from industry norms. While externally mirroring standard chrome-finished convection ovens, the interior architecture is fundamentally different. Every surface exposed to food, the cooking chamber, the racks, the rotisserie, is constructed from bare, uncoated metal.

By excising Teflon-style baskets and plastic interiors entirely, the unit is inherently PFAS- and BPA-free. HYSapientia states it does not use non-stick coatings in any models or accessories. Unlike synthetic polymers, stainless steel is chemically inert and does not leach compounds under high heat.

Transitioning to an all-metal construction introduces distinct operational characteristics. Stainless steel possesses superior heat retention, prompting HYSapientia engineers to pair the metal chassis with a robust 1800W heating element and a 360-degree convection fan. In benchmark testing, the unit roasted a whole chicken in under an hour and processed frozen chips in 15 minutes, a 30 per cent reduction in cooking time compared to conventional ovens, while utilising 85 per cent less oil than deep-frying.

Furthermore, steel resists the warping, cracking, and discolouration that frequently plagues plastic models subjected to repeated thermal cycling. The primary concession is form factor; industry reviewers have noted that the reliance on food-grade metals results in a noticeably bulkier and heavier appliance. The absence of a non-stick coating also necessitates traditional cleaning methods, where baked-on grease requires physical abrasion, though the steel components remain immune to the scratching and flaking that ruins Teflon pans.

In the modern consumer electronics market, health claims require rigorous independent validation to avoid accusations of superficial greenwashing. HYSapientia has obtained CE and UKCA markings, certifying compliance with health, safety, and electromagnetic standards in the EU and UK. The product meets the EU Restriction of Hazardous Substances directive, limiting heavy metals and other toxic materials. In North America, it carries FCC Certification for electromagnetic compliance and UL Listing, confirming it has passed independent electrical and fire safety testing.

HYSapientia reflects a shift in the appliance industry. As the regulatory noose tightens around forever chemicals, transparency regarding supply chains and material sourcing is transitioning from a niche marketing tactic to a core business imperative. Consumers now consider not only the food they eat but the materials used to prepare it. If stainless steel gains traction, larger manufacturers may need to reconsider their reliance on synthetic coatings. In a competitive market, material transparency could become a decisive advantage.