The tax on carbon Europe introduced at the beginning of the year may have some surprising knock-on effects. The higher cost to producers for exporting goods that were produced using carbon-intensive methods to Europe may drive some to clean up operations. In India, some producers are exploring the potential for transitioning to green steel to reduce emissions and cut export costs to one of its biggest markets.

India is one of the world’s main steel producers, and it has become a major supplier of the metal to the European market. India achieved its target steel production of 205 million tons a day in the 2024/2025 fiscal year and is expected to achieve an output of 300 million tons per year by the 2030/2031 fiscal year, according to a report by MP Financial Advisory Services LLP. As much as 60 percent of India’s steel exports are destined for the European Union.

However, in January, the EU introduced a world-first carbon tariff – the carbon border adjustment mechanism, which requires companies operating within the EU to pay levies on the import of goods whose production releases high levels of carbon emissions. This applies to heavy industries, such as steelmaking. Due to the new tariff, India’s steel producers could see their profit margins significantly decrease unless they decarbonize their operations.

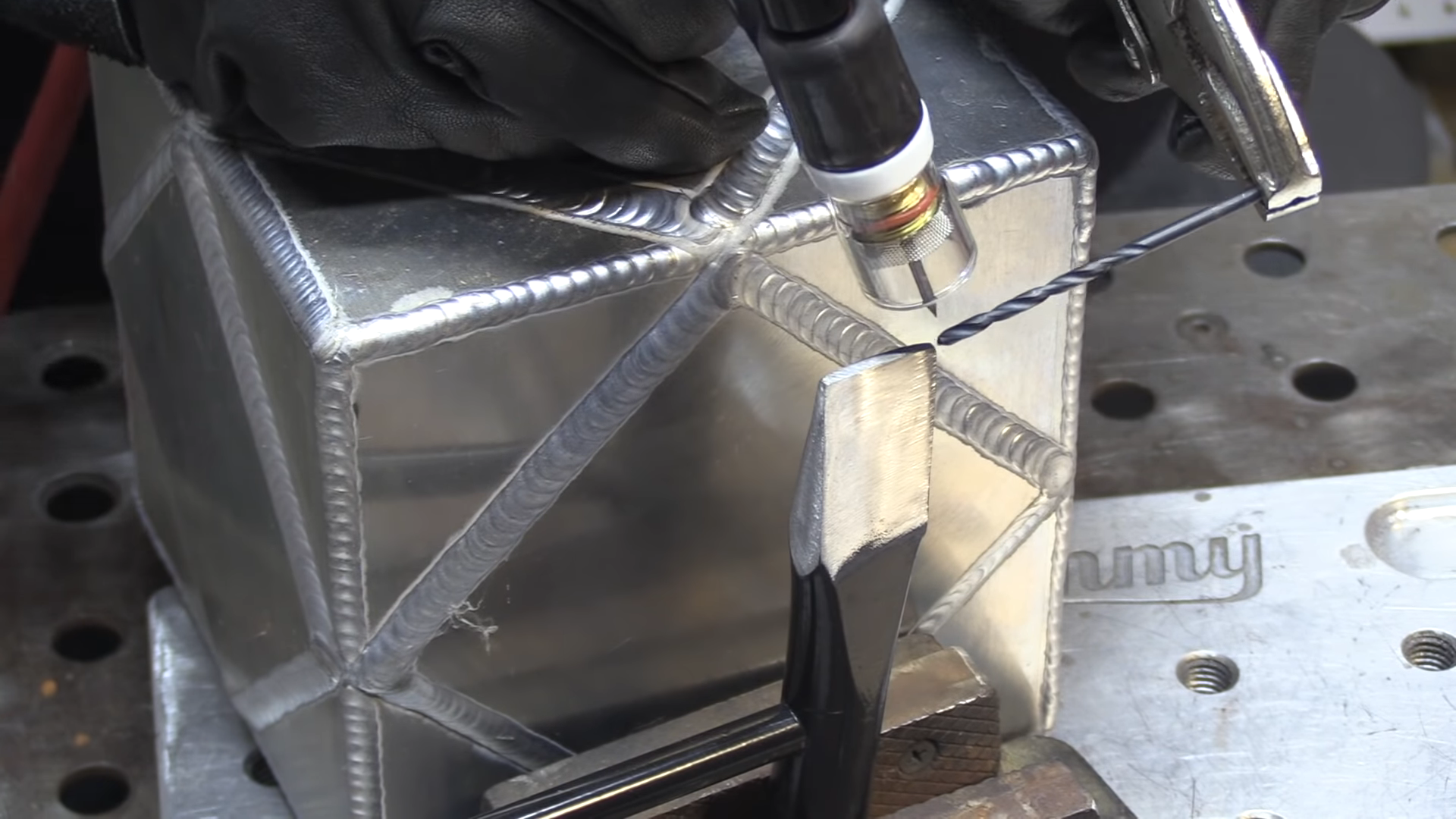

Steel is typically produced using coal to power operations, particularly in India. The coal powers a blast furnace, which is used to refine iron ore into iron, which is then transformed into steel in an oxygen furnace. This process is used in around 43 percent of India’s steel production.

The rest of India’s steel is produced using electric arc furnaces (EAF), an alternative to the basic oxygen furnace, which melts iron into steel using electricity. While this reduces operational emissions, the iron that goes into the furnace is still refined using coal. In addition to exporting large quantities of coal, India uses the fuel for around 75 percent of its power needs, meaning that the electricity used in its EAFs is not clean to start with.

The increased demand for cleaner steel production and fears over higher import fees in Europe are driving some of India’s steelmakers to develop infrastructure for direct reduced iron (DRI), a cleaner method of producing iron. However, in contrast to other parts of the world, where DRI facilities are powered using natural gas, India continues to rely on coal for power.

However, the Indian government is looking to gradually shift away from a reliance on coal in favour of renewable alternatives, having installed record amounts of solar panels and wind turbines in recent years. In September 2024, India’s Ministry of Steel published a 420-page report outlining the potential pathways for achieving green steel production, showing the political willingness to support the transition.

The government also released guidelines in 2024, classifying the criteria for green steel. It states that steel with carbon dioxide emissions of less than 2.2 million metric tonnes of carbon dioxide equivalent per tonne of finished steel is classified as “green”. The steel ministry explained, “The greenness of the steel shall be expressed as a percentage, based on how much the steel plant’s emission intensity is lower compared to the 2.2 mtCO2e/tfs threshold.”

While there is no agreed-upon international definition for green steel production, these guidelines provided Indian steelmakers with basic operational criteria. Nevertheless, achieving commercial-scale green steel production could still take several years.

In January, the Energy and Resources Institute (TERI) published a report entitled “Green Steel by 2030: Building the business case for the first green steel plant in India”, which assesses the conditions necessary to make commercial-scale green steel viable in India. TERI partnered with industry leaders to bridge knowledge gaps and offer a roadmap to accelerate the transition from pilot initiatives to commercial-scale projects.

Some producers in India are already putting their money where their mouth is, with Tata Steel announcing an investment of $1.2 billion in green steel technology in India’s Jharkhand state. India’s Tata Steel and the government of Jharkhand signed a letter of intent and memorandum of understanding at the World Economic Forum in Davos for the investment in innovative green steel technology in the region.

The funding is expected to contribute to the rollout of advanced iron production technologies, such as HISARNA, which allows the use of local coal and low-grade iron ore and reduces emissions using carbon capture systems, as well as EASyMelt, which is designed to reduce coke consumption by using synthetic gas. Tata Steel has already completed a successful pilot project in the Netherlands and plans to develop a new facility in Jamshedpur with a capacity of around 1 million tonnes a year by 2030.

While it could take several years for India to significantly decarbonise its steel production, private investments in research and development, and support from the government to transition away from coal, will likely advance the industry at an accelerated pace. Meanwhile, the new carbon mechanism in the EU is encouraging producers to reduce emissions to ensure that they can maintain strong profit margins going forward.

By Felicity Bradstock for Oilprice.com

More Top Reads From Oilprice.com